LuDong Mine Machinery Co., Ltd.

Mobile: 86-13589789857

Solution

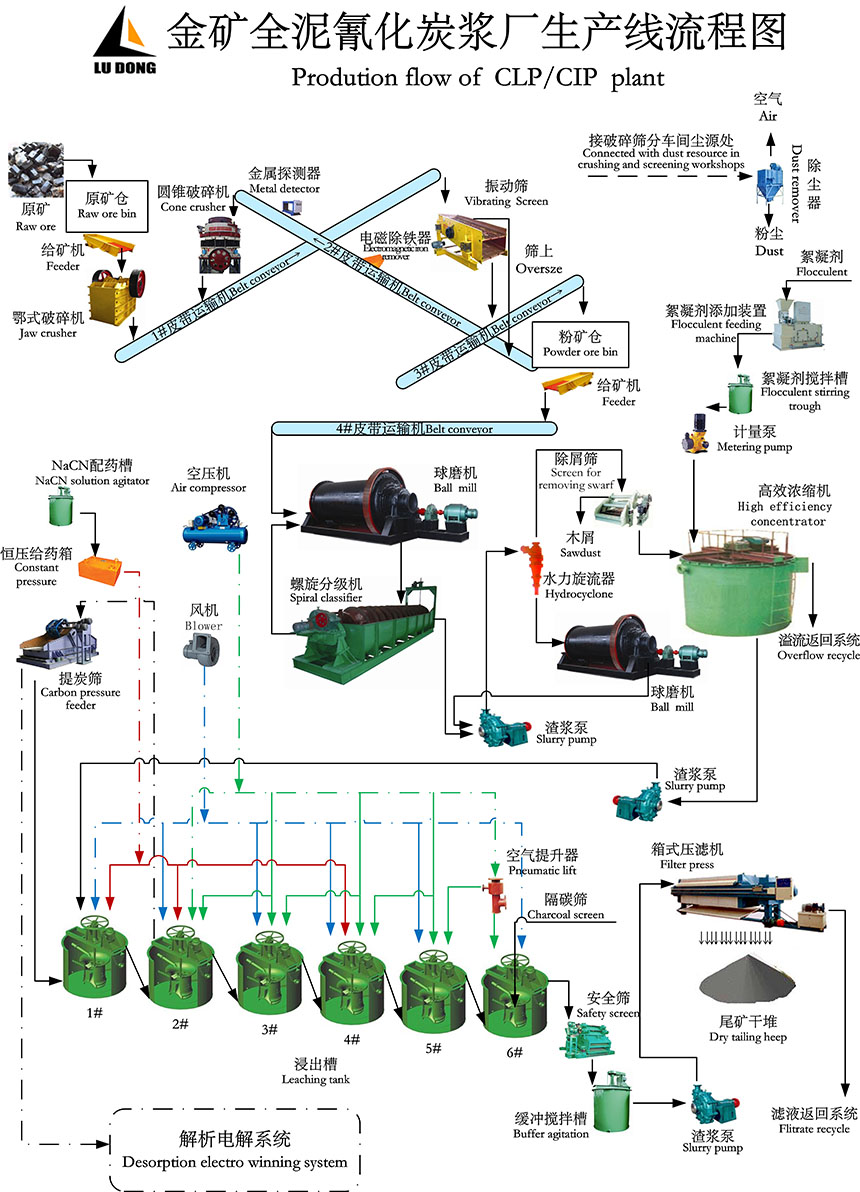

Gold mine full mud cyanide carbon pulp production

Gold mine full mud cyanide carbon pulp production

Mineral removal

The cyanide slurry should be treated with impurities such as wood chips before adsorption to prevent the wood chips from adsorbing the gold and activated carbon in the slurry to the carbon-rich, and prevent the wood chips from blocking the carbon screen.

Lip and Adsorption

Activated carbon is added to the leaching tank, and the activated carbon adsorbs gold in the slurry to become gold-loaded carbon. After the adsorption is completed, the activated carbon and the slurry are separated by a carbon sieve.

Desorption Electrolysis

In the closed system, the gold-loaded carbon can be quickly desorbed into gold mud and lean carbon under high temperature and high pressure conditions.

Smelting

After the obtained gold mud is simply pickled and removed, the gold ingot can be directly smelted.

Efficient and low-cost fast desorption electrolysis system

The system is characterized by high temperature, high pressure, no cyanide and desorption automatic control, and has the characteristics of high efficiency, rapidity and low consumption.

• Efficient: When the carbon content of the gold-bearing carbon reaches 3000g/t, the desorption rate can reach over 96%, and the lean carbon taste can be reduced by 50%-75% compared with the conventional desorption electrolysis device.

• Fast : desorption electrolysis temperature can be as high as 150 °C (30-55 °C higher than other models) system working pressure up to 0.5Mpa (0.2-0.5Mpa higher than other models), thus desorption The electrolysis time is very fast, generally 12 hours, shortening 50%-75%.

• Low consumption: The desorption electrolysis temperature is the same, no heat exchange is required, and the total power consumption is 1/2-1/4 of the conventional system due to the fast work.

• Cyanide-free: No sodium hydrogenation is required in the desorbent, low cost, no pollution

• Grade: Gold mud tastes high, no need for reverse electrolysis, gold mud extraction is easy

• Automatic Control : Specially set level control system, temperature control system and automatic control system

• Security: has triple security measures, namely, the system itself is intelligent, automatic pressure limiting pressure release mechanism, insurance safety valve

Processing equipment

|

|

|

|

|

Vibration feeding machine |

Jaw Crusher |

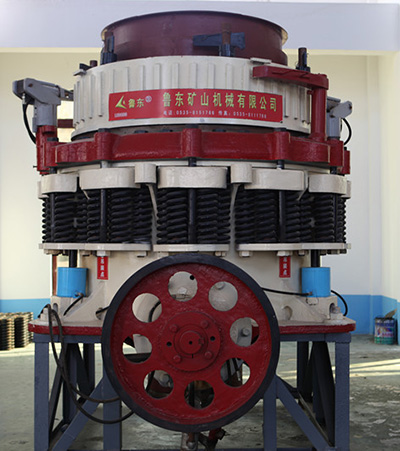

Cone crusher |

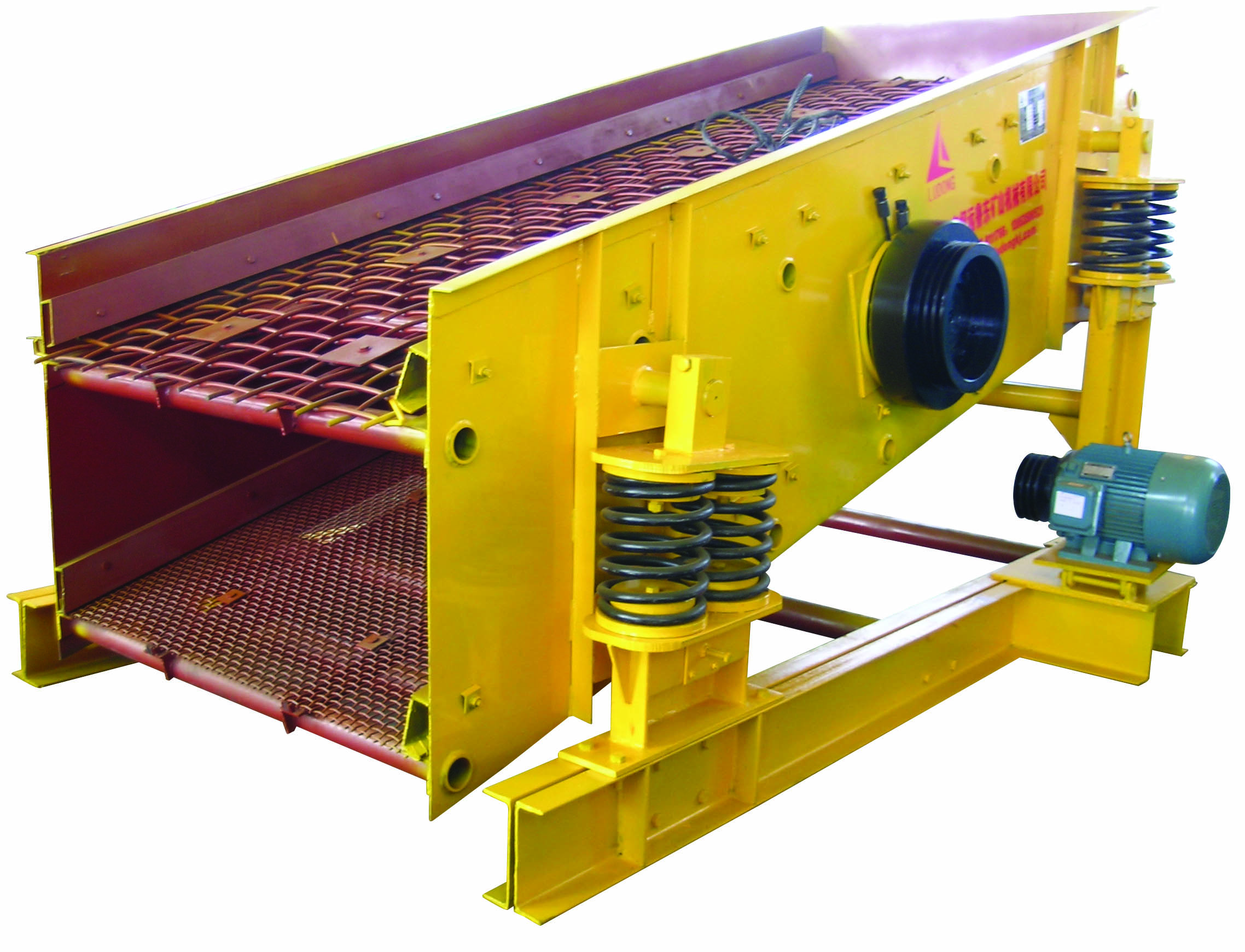

Vibrating screen |

|

|

|

|

|

Raft conveyor |

Ball mill |

Thickener |

Plate filter press |

|

|

|

|

|

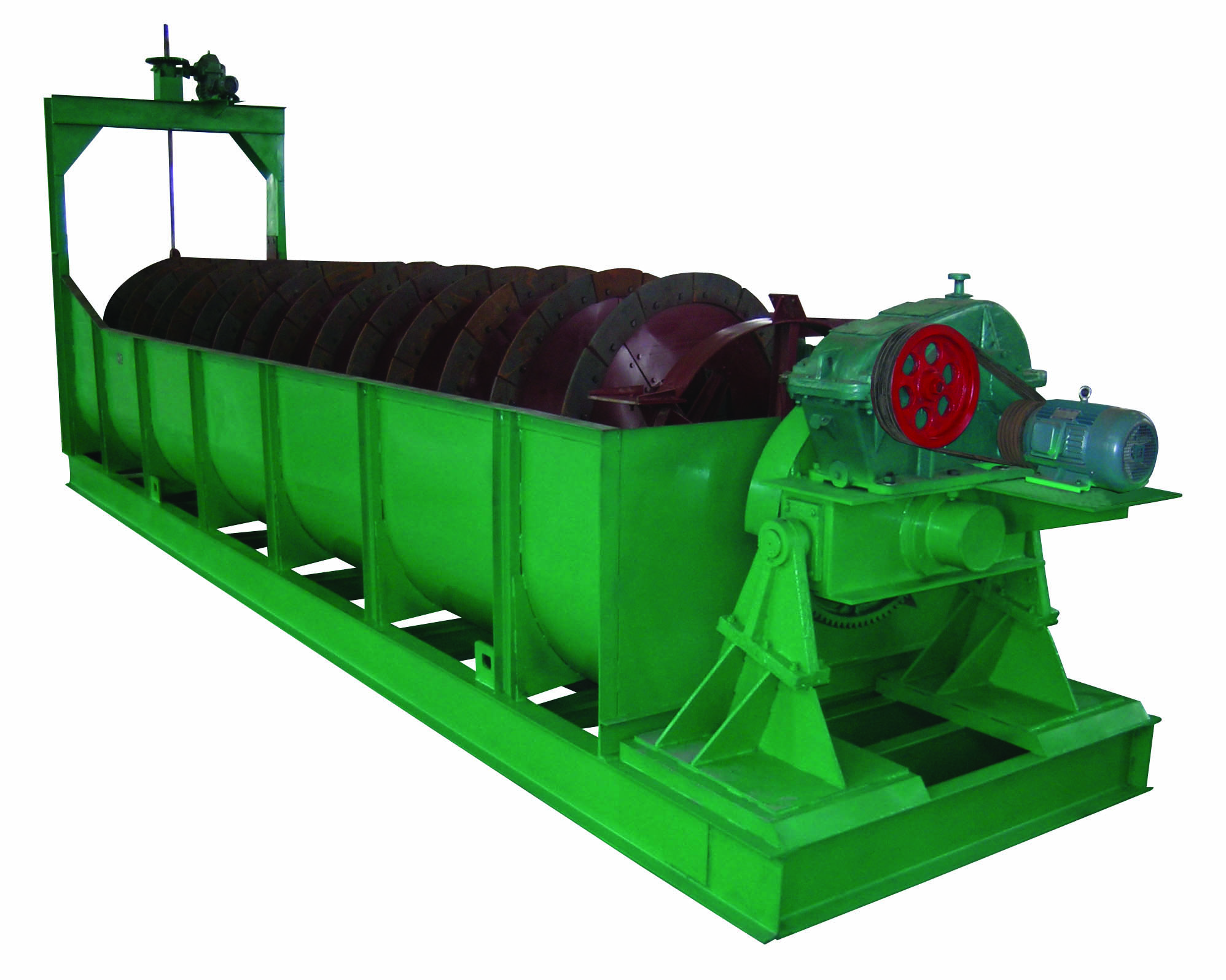

Spiral classifier |

XNT flocculant addition |

Carbon dip tank |

Desorption Electrolysis System |

PRODUCT CENTER

NEWS

SERVICE

Tel:+86-535-8117966 Phone:+86-13589789857(Mr Cao) E-mail: ldkuangji@163.com Add: No. 189, Zhaojin Road, Zhaoyuan City, Shandong Province, China

Copyright © LuDong Mine Machinery Co., Ltd. 鲁ICP备09077777号-1

ABOUT US