LuDong Mine Machinery Co., Ltd.

Mobile: 86-13589789857

Solution

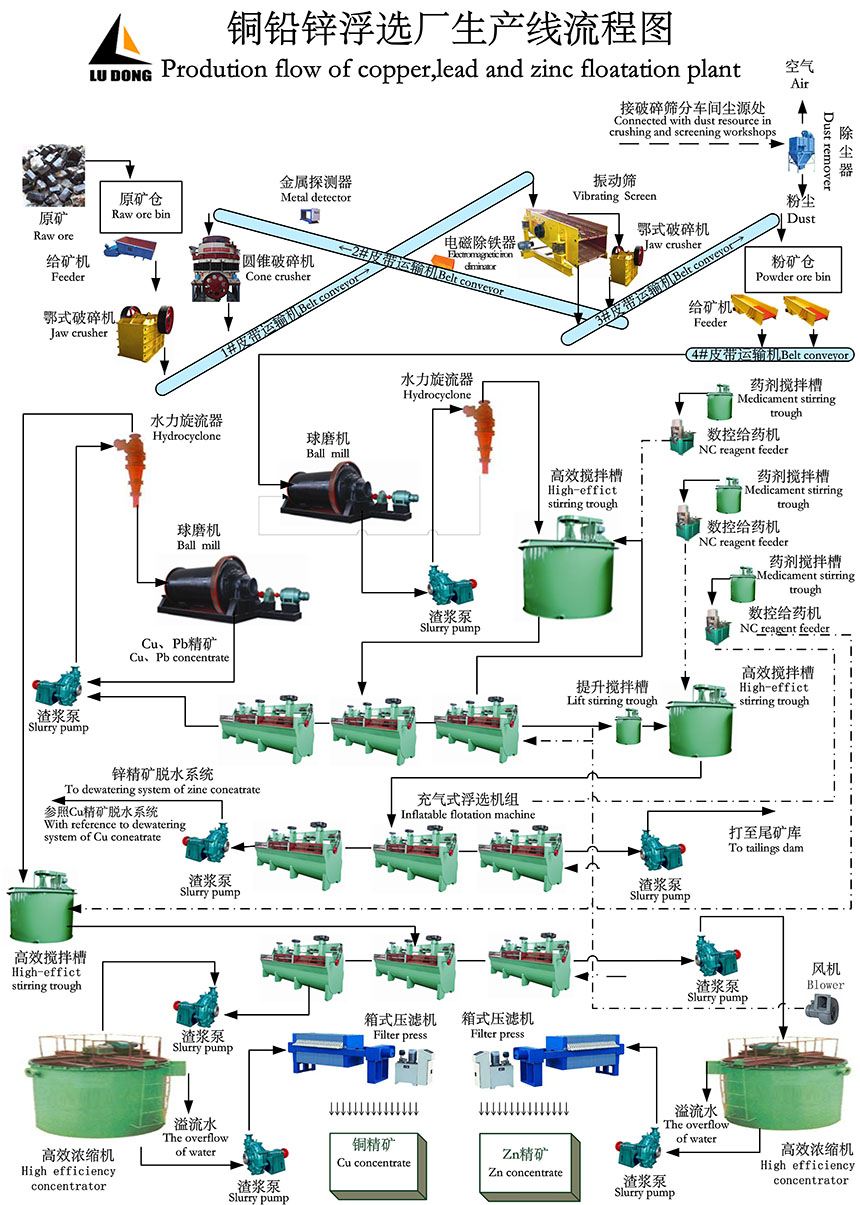

Copper, lead and zinc flotation process

Copper, lead and zinc flotation process

Mixing-separation flotation process---This process selects all fluidized lead and zinc sulfide minerals into mixed concentrates and directly discards tailings. Then, after the deionization of the mixed concentrate, the separation of lead and zinc is carried out, and the flotation separation effect is better

The process of mineral processing is novel and the operating cost is lower

The copper-lead mixed concentrate regrind process eliminates the need to finely grind all the ore, saving the cost of grinding, and re-grinding the concentrate to further dissociate the copper-lead concentrate, and has a good drug-removing effect. The separation creates favorable conditions.

Strengthen flotation process to improve copper concentrate grade

Strictly implement the pharmacy system in the rough selection section, control the dosage of the medicinal agent, and achieve the principle of "accepting early harvest and early harvesting", reducing the number of cycles and inaction loss; making full use of the secondary enrichment of foam, and adopting appropriate no water, The concentrate foam is rinsed to reduce impurities in the foam to enhance the flotation.

Processing equipment

|

|

|

|

|

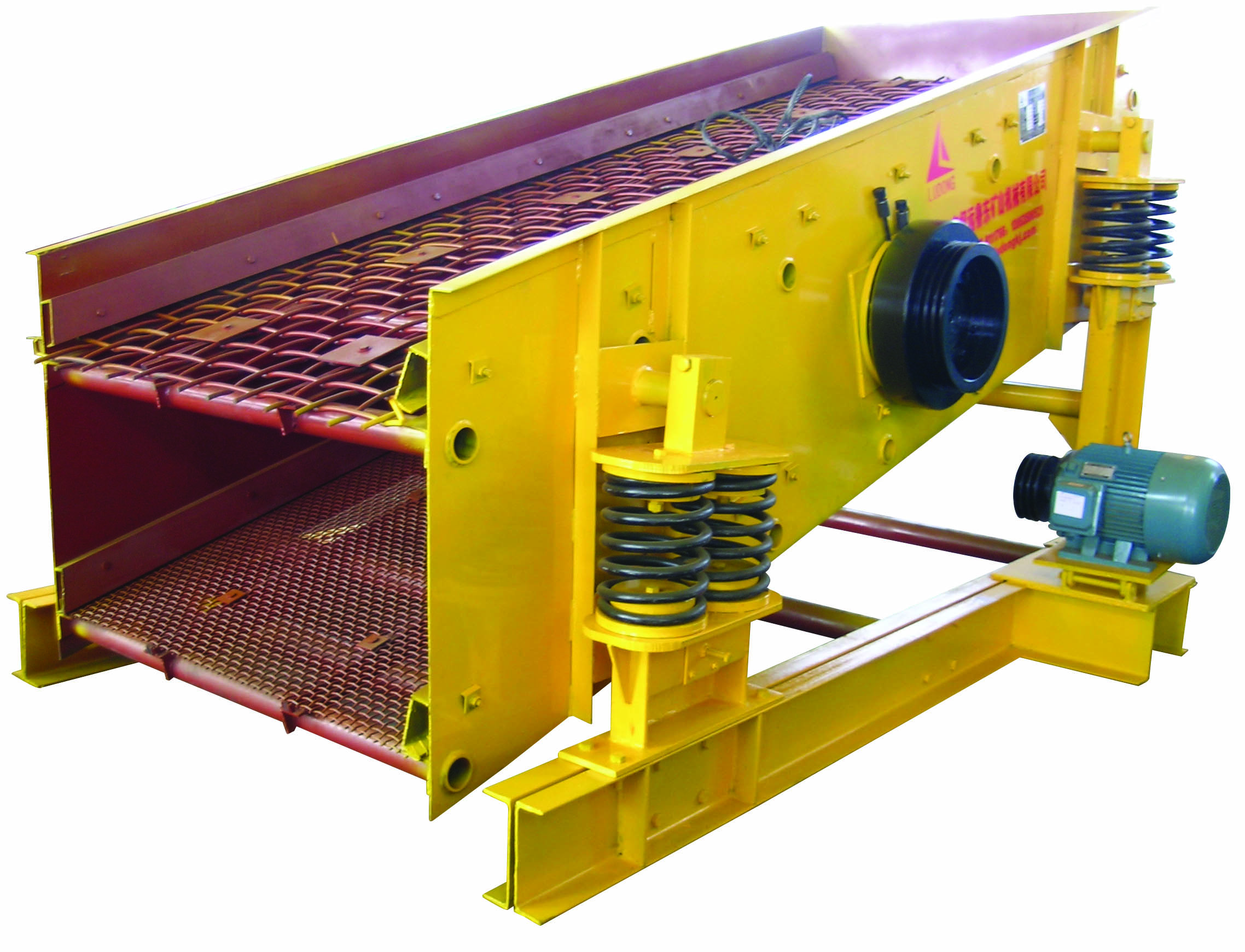

Vibration feeding machine |

Jaw Crusher |

High efficiency mixing tank |

Vibrating screen |

|

|

|

|

|

Raft conveyor |

Ball mill |

Thickener |

Chemical stirring tank |

|

|

|

|

|

Hydrocyclone |

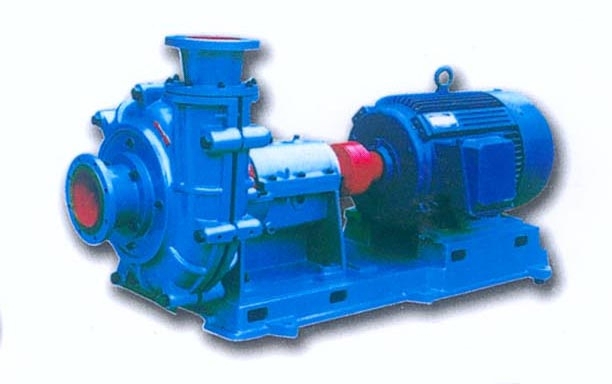

Slurry pump |

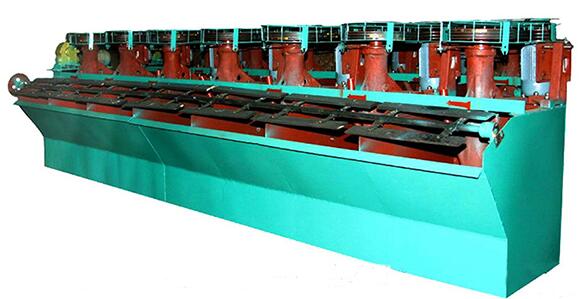

Flotation machine |

Plate filter press |

PRODUCT CENTER

NEWS

SERVICE

Tel:+86-535-8117966 Phone:+86-13589789857(Mr Cao) E-mail: ldkuangji@163.com Add: No. 189, Zhaojin Road, Zhaoyuan City, Shandong Province, China

Copyright © LuDong Mine Machinery Co., Ltd. 鲁ICP备09077777号-1

ABOUT US