LuDong Mine Machinery Co., Ltd.

Mobile: 86-13589789857

Solution

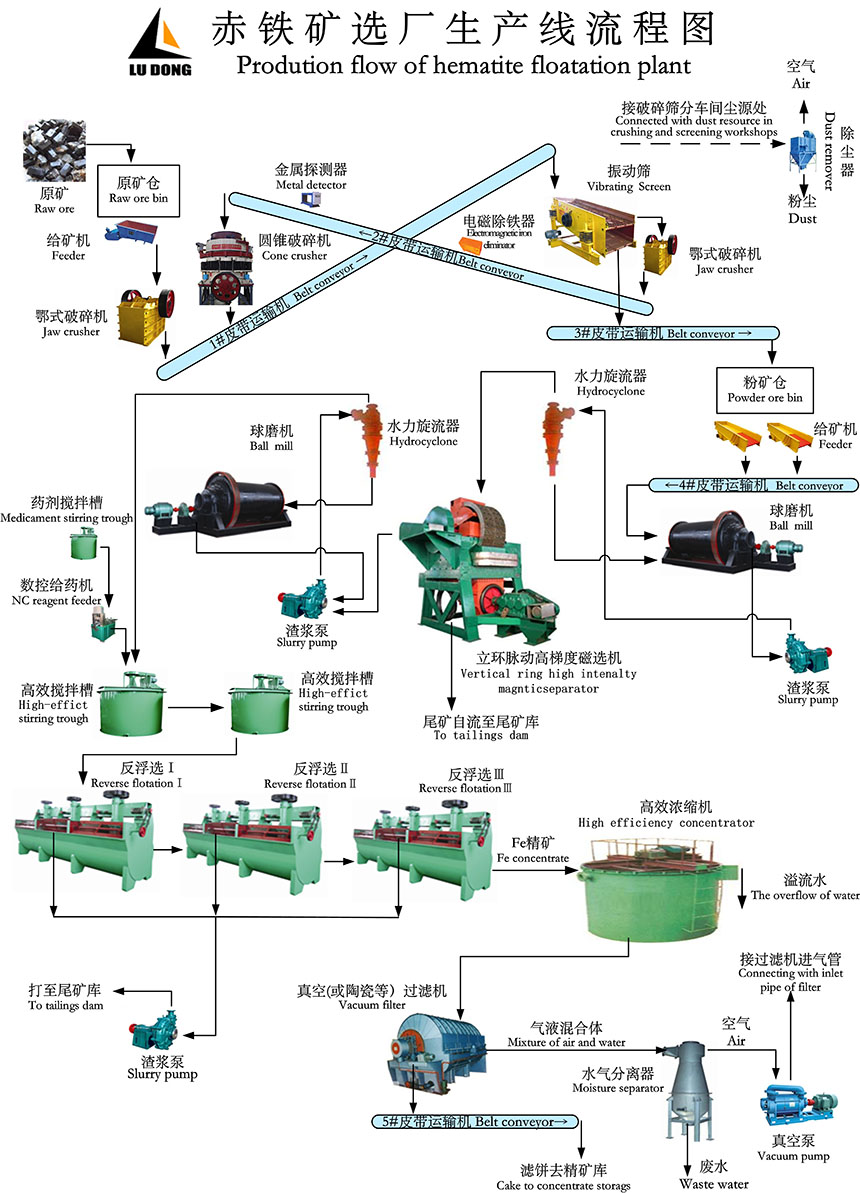

Hematite process

Hematite process

Stage grinding, reducing subsequent operations and reducing costs

The first stage of grinding classification adopts ball mill and cyclone to form closed-circuit grinding, which can ensure the classification efficiency and ensure the classification granularity; at the same time, some qualified concentrates can be sorted out in advance. And through the high gradient magnetic separator, some low-grade tailings can be discarded, which can reduce the amount of re-grinding of the mine and avoid over-grinding and reduce metal loss.

Adopting magnetic separation-flotation combined process, green environmental protection

The magnetic separation operation sorts out qualified coarse concentrates and tailings in time, which is in line with the principle of early harvest and early abandonment, and reduces the flotation operation and reduces the cost. Strong magnetic tail-reverse flotation process, less floating and more, economically more rational and strong magnetic process can recover fine-grain iron minerals, which can play the dual role of de-sludge and tail-splitting, creating better conditions for flotation operations; The reverse flotation process has a simple chemical system, which can significantly reduce the organic matter such as flotation reagents entering the slurry and reduce its adverse effects on the flotation process.

Process equipment

|

|

|

|

|

Vibration feeder |

Jaw crusher |

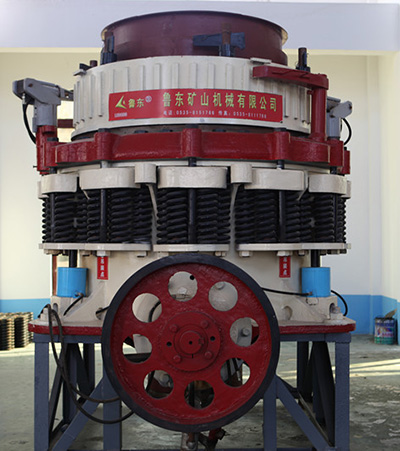

Cone crusher |

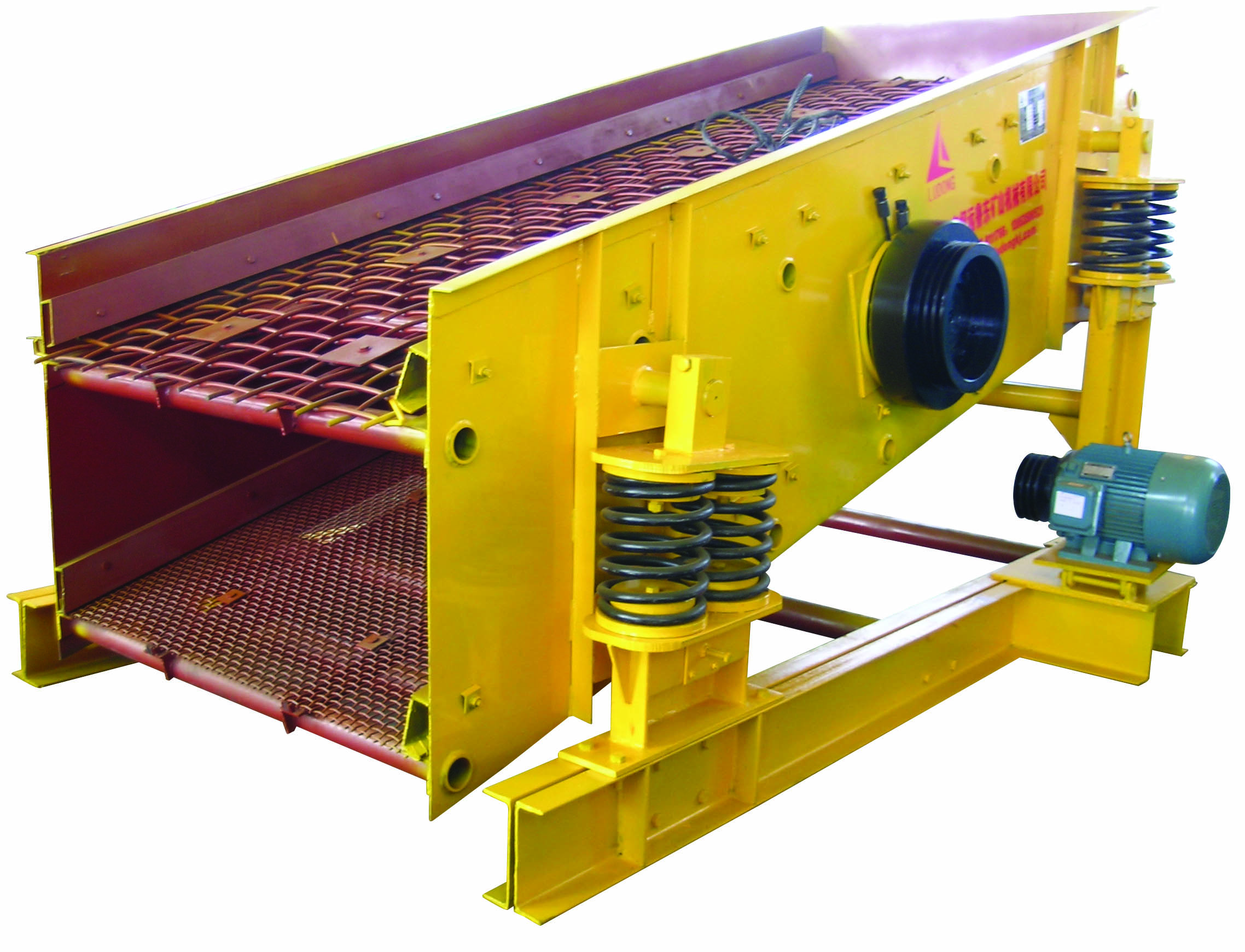

Vibration sieve |

|

|

|

|

|

Conveyor |

Ball mill |

Thickener |

ceramic filter |

PRODUCT CENTER

NEWS

SERVICE

Tel:+86-535-8117966 Phone:+86-13589789857(Mr Cao) E-mail: ldkuangji@163.com Add: No. 189, Zhaojin Road, Zhaoyuan City, Shandong Province, China

Copyright © LuDong Mine Machinery Co., Ltd. 鲁ICP备09077777号-1

ABOUT US