LuDong Mine Machinery Co., Ltd.

Mobile: 86-13589789857

Product center

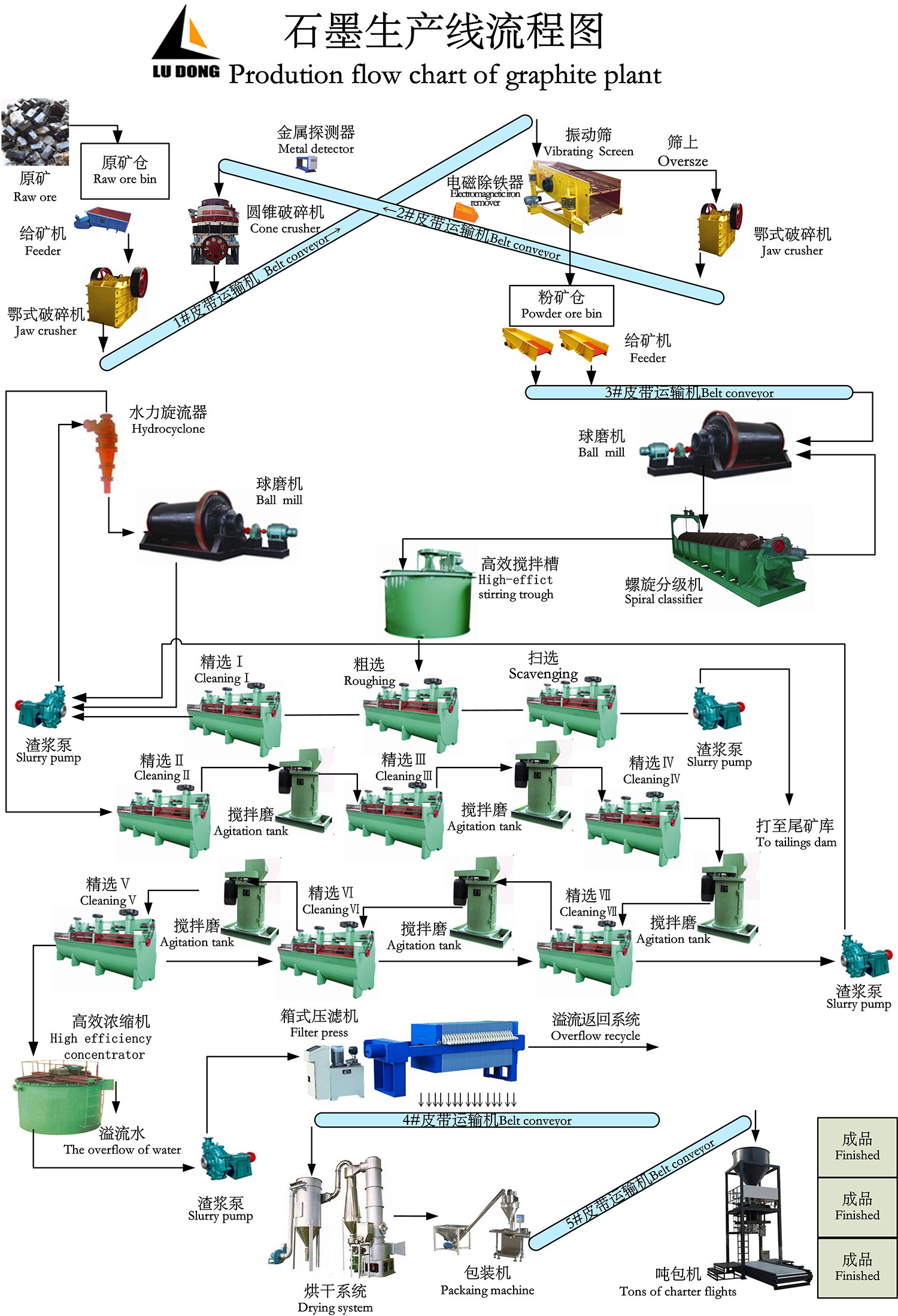

Inner Mongolia Wulanchabu 10000t/d graphite ore dressing plant project

Inner Mongolia Wulanchabu 10000t/d graphite ore dressing plant project

For the ore sample delivered by the client, the Ludong mining machine carried out an optional experimental task, and the main object of the ore dressing experiment was graphite. After stage grinding and stage selection, a graphite concentrate with a recovery rate of 94% can be obtained.

The first step: crushing and screening

Adopt two-stage open circuit process. One section uses a jaw crusher; the second section uses a hammer crusher. A vibrating screen is used in the screening stage.

Step 2: Grinding classification

Adopt a section of open grinding grading process. Through the ball mill, a section of grinding is carried out, and the discharged mineral material flows into the high-grade spiral classifier; the classifier is returned to the ball mill and re-grinded, and the classifier overflows from the flow to the flotation operation.

The third step: flotation equipment and tailings dehydration

The classifier overflows from the high-efficiency stirring tank and stirs the slurry to float. The tailings after flotation and coarse sweeping are used as the final tailings slurry pump to enter the cyclone component coarse ore and fine ore. The coarse ore flows to the dewatering screen and the dewatering screen is dehydrated to the tailings pond. The fine ore flows from the concentrator to the concentrator. After the concentrator is concentrated, it is sent to the filter press for dehydration. After dehydration, it is sent to the tailings pond.

The fourth step: concentrate dehydration

Select the concentrate from the previous stage as the final concentrate.

The concentrate slurry is first pumped to the defoaming buffer tank buffer by the slurry pump, and then dewatered by the double-stage pump to the filter press. After dewatering, the filter cake is transported to the concentrate storage tank for storage and drying by the belt conveyor. The filtrate flows from the concentrate to the concentrate filtrate tank, and is pumped to the production plant to return to the pool for recycling.

Step 5: Concentrate drying

The concentrate in the concentrate pool is transported to the drum drying equipment, the flow is controlled by the ash discharge valve, transported to the drum screen through the screw conveyor and into the silo, and the final product is filtered into the packaging machine through the rotary mobile screening machine. Charter machine.

Conclusion

The project provides one-stop tracking service from the beneficiation experiment, mine design, equipment manufacturing, installation and commissioning to the training of workers to the standard production. Ludong has always been committed to providing customers with more professional, more perfect and more efficient mineral processing equipment and plant selection solutions!

Process equipment

|

|

|

|

|

Sorghum spiral classifier |

Jaw Crusher |

Screw conveyor |

Circular vibrating screen |

|

|

|

|

|

Flotation machine |

Ball mill |

High efficiency mixing tank |

Plate filter press |

Flow chart

PRODUCT CENTER

NEWS

SERVICE

Tel:+86-535-8117966 Phone:+86-13589789857(Mr Cao) E-mail: ldkuangji@163.com Add: No. 189, Zhaojin Road, Zhaoyuan City, Shandong Province, China

Copyright © LuDong Mine Machinery Co., Ltd. 鲁ICP备09077777号-1

ABOUT US