LuDong Mine Machinery Co., Ltd.

Mobile: 86-13589789857

Product center

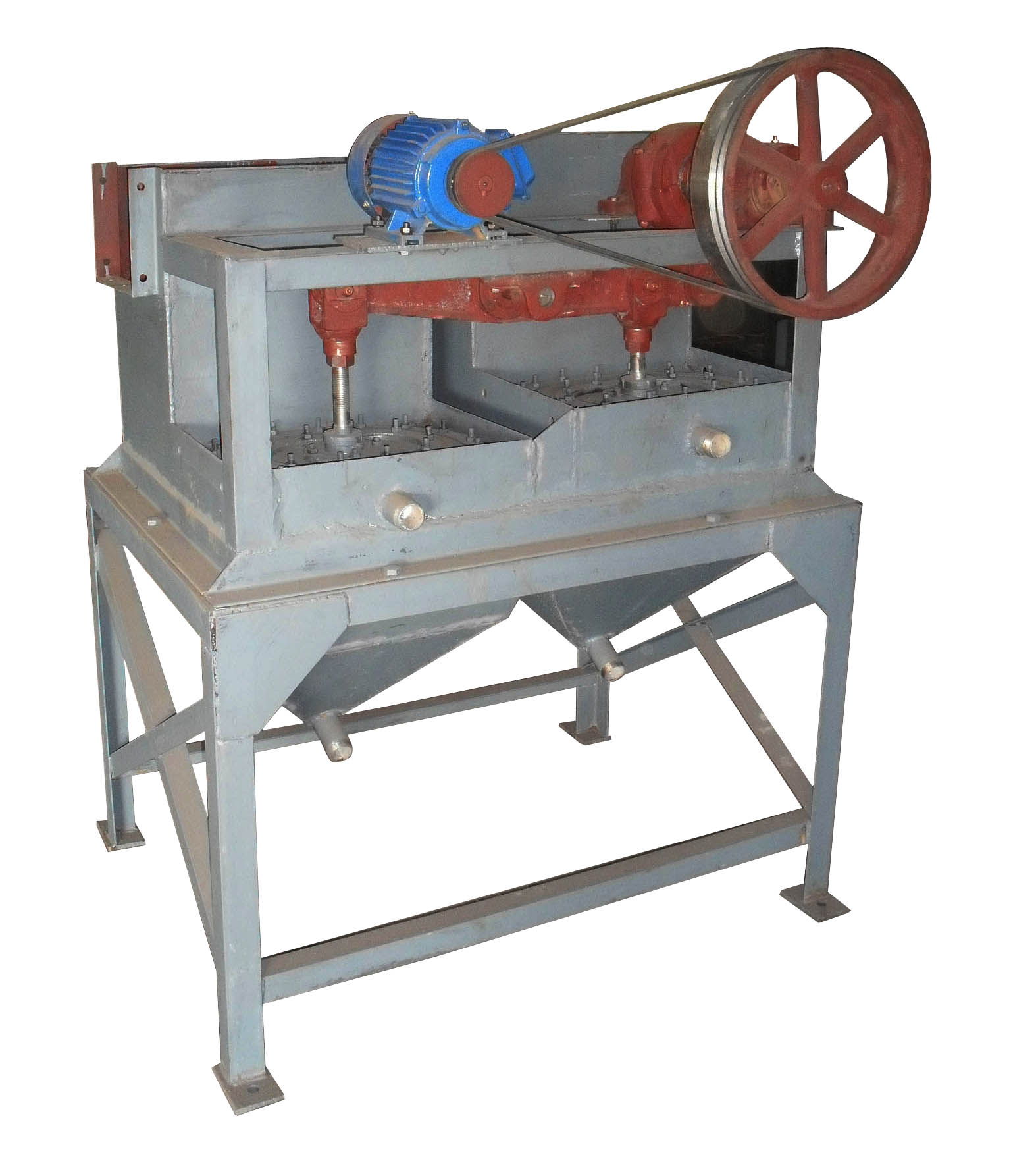

Diaphragm jig

Diaphragm jig

Advantage characteristics:

1. The film layer is relatively stable, the sorting effect is better, the diaphragm and the transmission device are on the side of the jig chamber, and the maintenance is convenient.

2. It is used to recover fine-grain grade high-grade ore. The gold-gold mine is used for sorting coarse ore concentrates. In the rock gold ore dressing plant, the monomer coarse-grained gold is recovered in advance in the grinding and classification circuit.

3. The design of the water distribution valve is adopted, and the transmission mechanism is linked to the water supply. The structure is unique and advanced, and reasonable water supply is realized.

working principle:

After the vibrating motor vibrates the fabric, the discharge amount can be precisely adjusted by the hand wheel. The magnetic roller is dragged by the speed regulating motor, and the speed of the rotation is adjusted by the speed regulating table to control the output of the magnetic separator and the concentrate grade. The ore particles are sent to the upper magnetic roller for sorting by the conveyor belt. Since the ore particles of the manganese ore are magnetic, they are immediately adsorbed on the magnetic roller by the strong magnetic field, and the gangue particles (miscellaneous sand, sand) are not magnetic (the magnetic is weak) ), the strong magnetic force of the magnetic roller does not generate suction force. With the rotation of the magnetic roller, the ore particles are always sucked on the magnetic roller, and the gangue particles are thrown off the separation plate when the magnetic roller is turned to the front end position. In front of the (the grade of the concentrate can be adjusted by changing the angle of the partition plate), the ore continues to be taken into the demagnetization zone by the magnetic roller and automatically falls into a selection of the mining hopper to collect the finished product. Due to the falling of the upper magnetic roller The gangue also contains some magnetic weaker ore particles, which will enter the lower magnetic roller to continue magnetic separation. After the magnetic separation, the finished ore particles enter the second selection of mining hoppers to be collected as finished products, and the gangue that is thrown out passes through the tailings. The mouth is discharged.

Technical Parameters:

Selection instructions: 1. In addition to the model and quantity, the size of the mesh must be indicated when ordering. No need to supply the 2mm mesh. 2. If there is no special requirement for the transmission model, it will be produced in a seated manner. 3, the jigging room is divided into single and double bucket for the user to choose, must be specified when ordering.

|

Diaphragm jig technical reference table |

||||||||||

|

规格(mm) |

给料粒度(mm) |

生产量(t/h) |

冲次(次/min) |

冲程调节范围(mm) |

给矿浓度(%) |

补充水量(t/h) |

电机型号 |

电机功率 |

外形尺寸(mm) |

重量(kg) |

|

Model |

Size of supplying minerals |

Output |

Washing times |

Regulating limits of |

Density of supplying mineral |

Measure of additional water |

Motor Model |

Motor Power |

Dimension (L×W×H) |

Weight |

|

双斗 300*450 |

1~12< |

2.1~6.1< |

322~420< |

0~25.3 |

15~50 |

2.1~3.8 |

Y90S-4 |

1.1 |

1290*1270*1750 |

745 |

|

双斗 300*450A |

1~12 |

2.1~6.1 |

322~420 |

0~25.3 |

15~50 |

2.1~3.8 |

Y90S-4 |

1.1> |

1230*1270*1740> |

550 |

|

单斗 300*450> |

≤10 |

2~5 |

300 |

0~18 |

15~50 |

1~2 |

Y90L-6 |

1.1 |

650*1030*1588 |

320 |

|

单斗 400*600A |

≤10 |

2~5 |

300 |

0~18 |

15~50 |

2.1~5.4 |

Y90L-6 |

1.1 |

792*1237*1894 |

400 |

|

单斗 400*600 |

≤10 |

2~5 |

76.7~767 |

0~18 |

15~50 |

2.1~5.4 |

TZT222-4 |

1.1 |

996*1263*1789 |

500 |

|

单斗 600*900 |

≤10 |

2~5 |

300 |

0~25 |

15~50 |

2..1~6 |

Y112M-6 |

1.1 |

1638*1230*2148 |

1400 |

PRODUCT CENTER

NEWS

SERVICE

Tel:+86-535-8117966 Phone:+86-13589789857(Mr Cao) E-mail: ldkuangji@163.com Add: No. 189, Zhaojin Road, Zhaoyuan City, Shandong Province, China

Copyright © LuDong Mine Machinery Co., Ltd. 鲁ICP备09077777号-1

ABOUT US